Install a code‑compliant fence in Sycamore completed properly from day one. Our licensed professionals handle permitting, homeowner association clearance, utility location services (811), and property boundary verification. We plan layout, set posts to frost depth, align rails, and hang gates to spec. Select from multiple fencing options like wood, composite, vinyl, ornamental metal, or chain link-matched with corrosion-resistant hardware and protected coating systems. Expect precise measurements, drainage planning, inspections, and a written timeline and warranty. Find out how different materials, styles, and installation schedules suit your location.

Essential Points

- Experienced, qualified fence specialists in Sycamore taking care of required documentation and inspections with verified property line and utility clearances.

- No-cost on-site evaluations, laser-accurate layout planning, and detailed site plans for gates, setbacks, slopes, and drainage.

- Professional installation: posts set to frost depth, featuring accurate alignment, anti-corrosion hardware, and concrete bases crowned for water runoff.

- Material choices available featuring composite, cedar/PT wood, vinyl, ornamental metal, and chain link offering proper height requirements, pool safety spacing, and warranty coverage.

- Detailed warranty periods and schedules; service packages feature yearly hardware inspections, coating renewals, and drainage improvements.

The Importance of Professional Fence Installation in Sycamore

Begin with professional knowledge that avoids costly mistakes: professional fence installers in Sycamore are familiar with ground composition, property lines, and municipal codes, guaranteeing your fence meets setback, height, and visibility requirements the first time. You'll prevent boundary conflicts, improper placement, and correction orders because licensed crews verify boundaries, arrange for utility locates, and document approvals. Their professional expertise guides proper installation specifications and gate clearances that remain code-compliant.

You'll also get liability coverage. Professional contractors carry general liability and workers' compensation, safeguarding you from property damage and injury claims. They utilize code-approved fasteners, weather-resistant materials, and proper safety protocols, while furnishing written warranties and as-built records. With proper positioning, plumb lines, and proper tension, your fence works perfectly and meets all inspection requirements.

Fence Materials and Styles for Homes and Businesses

After handling the permitting and layout correctly, you can direct your attention to choosing fence styles and materials that meet Sycamore's requirements for performance, maintenance, and code. For minimal care, select recycled composite panels; they guard against rot, insects, and warping while meeting height and setback standards. Wood provides warmth but needs sealing; treated pine or cedar performs best with code-appropriate post depth and fasteners. Chain link delivers cost-effective security; add privacy screens where authorized to enhance opacity without exceeding height limits. Ornamental metal (steel or aluminum) offers durable, pool-compliant options with code-specified picket spacing. Vinyl remains stable, cleanable, and perfect for residential boundaries. Bamboo fencing can work as a decorative screen; confirm local allowances for wind load and decay resistance. Be sure to verify gate hardware, visibility, and clearance requirements.

Customized Solutions: Aligning with Your Property's Style and Requirements

Make sure to align the fence design to complement your building's architectural aesthetic to maintain a unified look and meet local design standards. Select materials and finishes that match existing components, satisfy durability specifications, and meet HOA and building codes. Consider access points, visibility, and spacing to maximize security and access while following height limits, boundary requirements, and spacing requirements.

Aligning Architectural Styles

Even though height requirements, setbacks, and materials should follow local regulations, optimal outcomes depend on harmonizing the design with your property's architecture and functional needs. First identifying your home's governing style-Mid‑Century, Colonial, Craftsman, or Contemporary-and reflect its patterns, proportions, and elements in the fence profile and post spacing. For historic preservation districts, comply with official requirements, protect significant sightlines, and detail any suggested aesthetic differences to justify compatibility.

Match highest points to porch railings and roof angles, ensure gate dimensions match walkway geometry, and size posts to building mass. Keep transparency around primary elevations to protect streetscape character and sight triangles. Integrate corner returns, datum lines, and trim profiles for continuity. Confirm setbacks, sight-distance specifications, and easements before layout to ensure compliant, unified alignment.

Material and Finish Selections

The choice of materials and finishes greatly affects durability and unity more than any other factor. Select materials that satisfy regulatory standards, weather requirements, and maintenance goals. Budget-friendly pressure-treated pine works well and readily accepts stains; cedar and redwood provide inherent oils and exceptional weather resistance. For optimal longevity, opt for powder-finished steel or aluminum with AAMA-certified coatings; in seaside locations, use corrosion-resistant metals. Vinyl delivers consistent color and minimal maintenance but needs UV-protected compounds.

Match finishes with surrounding elements and modern color patterns without sacrificing longevity. Implement absorption-based treatments on wood to prevent separation; select low-VOC options as needed. For metals, specify zinc-aluminum or galvanized base materials under powder coating. Validate hardware: stainless fasteners, compatible brackets, and dielectric separation to prevent galvanic corrosion. Document maintenance schedules and warranty terms in writing.

Layout Organization Strategy

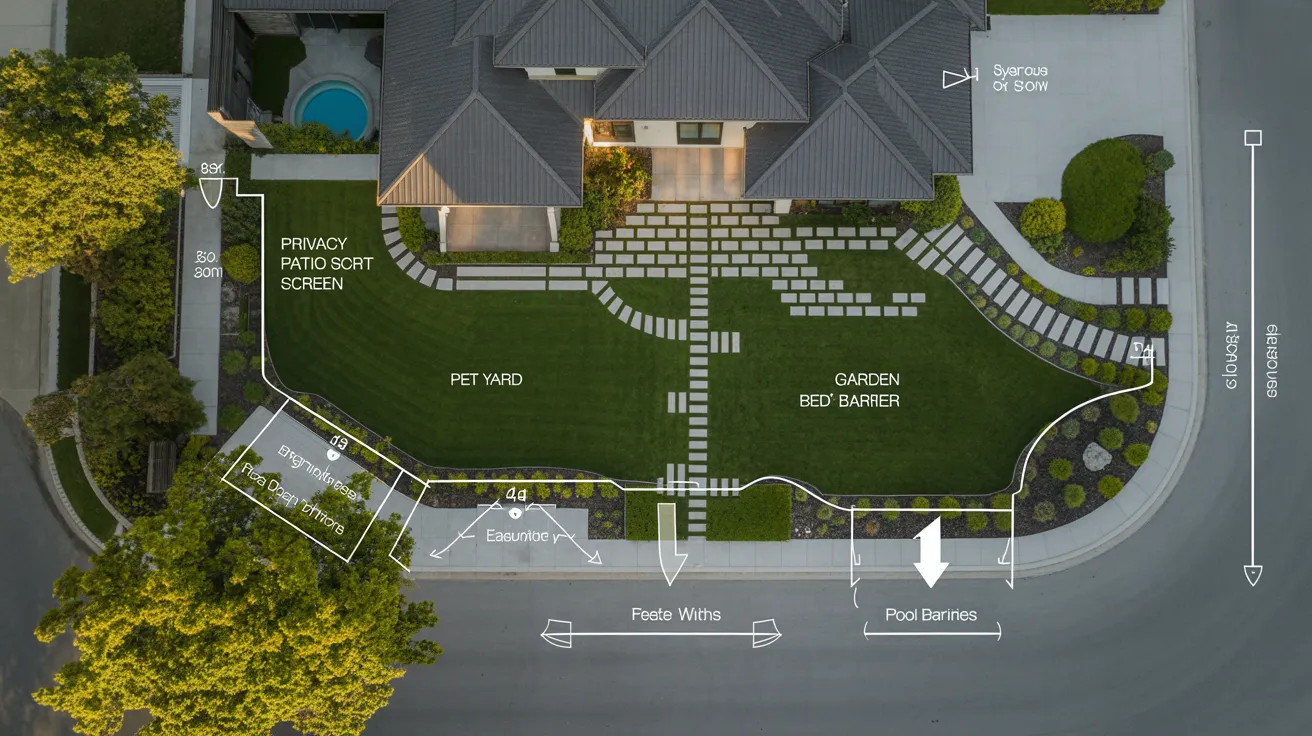

Prior to marking fence lines, start by establishing functional zones and verify compliance with local regulations and site limitations. Layout key access points, vehicle paths, and service zones to maintain proper circulation. Designate areas for privacy, pets, swimming pools, and gardens, then determine gate dimensions to accommodate machinery and emergency vehicle entry. Place gates strategically to maintain clear access to service meters, utility controls, and access rights; don't obstruct established rights-of-way.

Verify fence details against city ordinances and community rules concerning dimensions, visibility, and positioning. Preserve required corner visibility and ensure proper drainage pathways to stop water from collecting near foundations. Space posts according to terrain features and building attachment locations for optimal stability. Use heavy-duty components at regularly accessed entrances. Design lighting and latch systems to satisfy security requirements, specifically for pool barriers. Document all dimensions on a properly scaled layout.

Regulatory Requirements and Property Line Considerations

Before starting any fence installation, you must confirm all local codes, permits, and zoning requirements before any post placement. Get written authorization for placement, materials, and height, and verify zoning setbacks for roadways, easements, and alleyways. Verify HOA restrictions where necessary. Call 811 and record utility clearances prior to digging; numerous areas require verification. Perform survey verification to confirm the official property boundary; don't rely on old fences or assumptions. If markers are missing, hire a licensed surveyor.

Follow corner visibility rules at corners and adhere to pool safety standards and wildlife regulations where needed. Secure neighboring property consent when building close to shared boundaries; documented consent reduces future disputes. Keep documentation on-site and coordinate required inspections when required. Keep paperwork-like certifications, surveys, and notifications-for final approval.

Project Planning, Site Assessment, and Measurements

Begin by evaluating the property layout, documenting grade changes, utilities, easements, and required setbacks to verify compliant fence placement. Set up accurate measurement protocols: establish control lines, place benchmarks, calculate center-to-center post spacing, and record offsets for gates and corners. Document all dimensions and constraints in a site plan to direct material takeoffs, cut lists, and a regulation-compliant installation sequence.

Layout Configuration Analysis

Although the fence style and materials matter, your project succeeds or fails with a comprehensive site assessment. Start by confirming property lines against recent survey documents and recorded easements; designate setbacks as per local ordinance. Identify utilities through 811 and note overhead clearances. Conduct a vegetation survey to spot trees, roots, and invasive species that could conflict with post locations or long-term stability. Perform drainage analysis to track slope, low points, and discharge paths so fence lines don't create water buildup or compromise footings. Note driveway aprons, ADA routes, gates' swing arcs, and required sight triangles at streets. Document soil classifications and frost depth to inform footing design. Record surface improvements-retaining walls, patios, irrigation-so alignment remains code-compliant and constructible.

Measurement Accuracy Guidelines

Once confirming the site constraints, establish a fixed baseline and datum, then take measurements from control points to avoid cumulative error. Use benchmark nails or stakes set outside excavation limits. Check property corners with survey equipment and reconcile any deed, plat, or GIS discrepancies. Perform laser calibration before layout; verify instrument level and compensate for slope. Use stretched measuring tapes or employ a total station to set fence lines, offsets, and gate clearances. Record horizontal and vertical data, including top-of-post elevations, drainage fall, and utility separations per code. Mark post centers at specified spacing, modifying for corner, end, and gate posts. Validate diagonals to confirm squareness. Note tolerances, required clearances, and obstructions. Protect all control points until concrete cures and final inspection.

Installation Process: From Post Setting to Final Finish

Start with accurate layout and code inspection, then you'll position corners, extend your lines, and mark post centers at code-approved spacing. Dig to frost depth, bell the bottoms if required, and secure posts in 5:1 gravel-concrete mix, sloped for water flow. Verify plumb and post alignment with a level and stretched line; support until cure. Mount rails per manufacturer span specifications, prepare fasteners, and ensure consistent reveal at gates and terminations. Hang panels or boards with even gaps and corrosion-resistant hardware. Adjust top line for grade, then cut posts to specified height. Seal or flash posts where required. Sand exposed cuts, seal end grain, and apply finish selection to match local guidelines. Conduct a final inspection, confirming clearances, fastener torque, and code compliance.

Product Care, Longevity, and Warranty Information

While visual appeal is important, lasting performance is determined by choosing the right materials, protective treatments, and regular maintenance schedules. Choose materials designed to withstand weather conditions, then pair them with galvanized or stainless hardware to eliminate galvanic corrosion. Use concrete footings beneath the frost line and implement UV-resistant finishes as per manufacturer schedules. If you prefer eco materials, opt for FSC-certified wood or reclaimed composite materials that comply with local code requirements and fire safety standards.

Conduct annual checks to secure all fasteners, keep soil away from structure, and maintain finish protection as needed. Ensure proper drainage to prevent moisture absorption. Quickly substitute any damaged pickets and damaged top pieces to prevent |Fence Sales Of Sycamore further issues.

Examine warranty conditions in documented format. Request multi-year coverage for materials, fasteners, and workmanship, with clear limitations, transfer options, and service conditions to ensure warranty remains active.

Request a Local Estimate and Schedule for Your Fencing Project

Get a detailed pricing by getting comprehensive estimates from licensed, insured fence professionals in your area, detailing fence style, height, linear footage, gate requirements, and site conditions. Request each contractor to verify utility locations, property line confirmation, and code setbacks. Ask for a written timeline estimate specifying preparation, post setting, concrete cure, panel assembly, and inspection scheduling.

Confirm who handles building permits, HOA authorization, and inspection arrangements. Share information about soil conditions, tree root presence, terrain gradients, and accessibility limits so crews can accurately price machinery and workforce expenses. Ask for separate quotes for disposal services, rock drilling, premium concrete options, and gate accessories. Review and compare workmanship warranties and material specifications by item number. Establish key phases with payment triggers tied to inspections. Secure start and completion dates in writing, with climate considerations and modification terms clearly outlined.

FAQ

What Impact Do Sycamore's Seasonal Weather Patterns Have on Installation Scheduling

The climate in Sycamore directly influences planning installation work. Professionals stay clear of winter construction periods to avoid freeze-thaw cycles affecting post stability and concrete curing. The ideal times are late spring or early fall for balanced soil moisture and reliable weather. Projects plan around wet weather patterns to maintain trench stability and foundation strength. When pollen counts rise, extra attention safeguards coating applications, while complying with local regulations for frost depth requirements, drainage requirements, and setback inspections to ensure lasting results.

Can You Integrate Gates With Smart Locks or Access Control Systems?

Yes. We can connect gates with smart locks and full access control systems. We offer smart entry with RFID, keypad integration, Wi‑Fi controllers, and Bluetooth. We'll recommend weather‑rated hardware, UL‑listed power supplies, and secure enclosures. We manage grounding, low‑voltage wiring, conduit, and surge protection to comply with local codes and NEC. You'll have access to schedules, app control, remote overrides, and audit logs. We also implement fail‑secure/fail‑safe per egress and fire code.

What Financing or Payment Plan Options Are Available for Fence Projects?

Pick from flexible payment terms, promotional zero-interest periods, and delayed payment options pending qualification. We offer milestone-based payment schedules that coordinate with construction phases. You can expect clear documentation with no hidden charges and fully compliant documentation. We assist with cost management, including material alternatives and project adjustments to achieve your financial goals. Make payments via electronic transfer, card payment, or check. Contact us regarding early payment discounts and extended terms for larger projects.

What About Removing and Recycling Old Fencing?

We take care of environmentally responsible removal of old fencing. We frequently hear from customers upon delivery of their new fence, worried about material disposal. You won't have to be. We safely dismantle posts, rails, and footings, categorize metals, wood, and composites, and deliver them to certified recyclers or compliant landfills. We seal concrete bases, follow local code, supply disposal documentation, and ensure a tidy workspace. You authorize the process; we handle the removal.

Are HOA Approval Support Services Available, Including Drawings and Documentation?

Indeed, you receive full HOA approval support. We offer HOA consultations, develop architectural drawings, specifications, and product information, and prepare necessary forms. We manage permit processing concurrently, ensuring setbacks, height limits, and visibility standards comply with code and HOA covenants. You get stamped site plans when needed, photo simulations, and timely revisions. We process packets, track reviews, address comments, and deliver final approvals so you can plan installation efficiently.

Final Overview

You might be tempted to DIY the boundary measurements, bypass official permissions, and end up with a fence that looks more artistic than intended. Instead, let professionals take care of surveys, setbacks, and quality materials, ensuring your installation is precise and your neighbors stay happy. We promise seamless integration with your property, full code compliance, and professional setup covering all aspects including ground conditions to weatherproofing. You can expect a comprehensive punch list, definite completion dates, and a perfectly installed fence that's straight, legal, and exactly right.